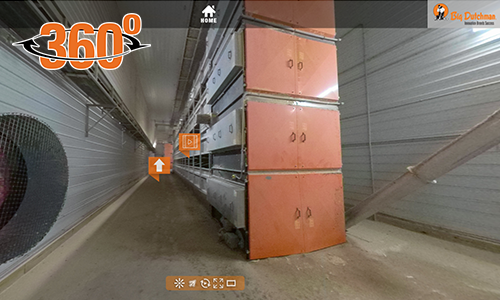

Optimizing production from rearing to laying

Whether you’re new to aviary systems or looking to refine your flock management, this interview offers valuable insights and practical tips for setting your pullets, and your production, up for long-term success.